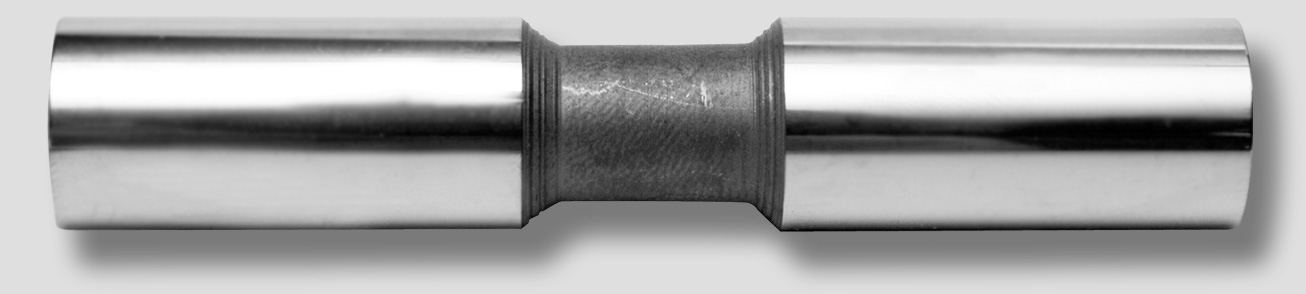

Class X Pin Gages

plus 40 millionths, minus nothing.

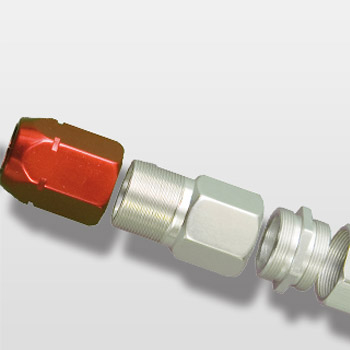

You may know them as pin gages, plug gages, or Go and No-go gages. Whatever the name you use, we’ve been the standard of quality measurement gages since 1955. In fact, we’ve originated so many unique features in our pin gages that we’ve been granted a patent by the USPO.

Deltronic takes gages seriously.

More than 20,000 Sizes In Stock

10,081 Inch Sizes – every .0001″ step from .0040″ through 1.0120″

10,241 Metric Sizes – every .0025mm step from .1000mm through 25.7000mm

| Diameter Size | Length | One | 2 - 4 | 5-9 | 10+ | 50+ |

| .0040” - .0150” .1000mm -.3800mm | 1 7/8” 47.62mm | 34.00 | 33.00 | 32.00 | 31.00 | 30.00 |

| .0151” - .0247” .3825mm - .6275mm | 1 7/8” 47.62mm | 32.00 | 31.00 | 30.00 | 29.00 | 28.00 |

| .0248” - .1080” .6300mm – 2.7425mm | 2 1/4” 57.15mm | 26.00 | 25.00 | 24.00 | 23.00 | 22.00 |

| .1081” - .3872” 2.7450mm – 10.0350mm | 2 1/2” 63.50mm | 25.00 | 24.00 | 23.00 | 22.00 | 21.00 |

| .3873” - .6375” 10.0375mm – 16.1925mm | 3” 76.20mm | 28.00 | 27.00 | 26.00 | 25.00 | 24.00 |

| .6376” - .8370” 16.1950mm – 21.2575mm | 3 1/2” 88.90mm | 32.00 | 31.00 | 30.00 | 29.00 | 28.00 |

| .8371 – 1.0120” 21.2600mm – 25.7000mm | 3 1/2” 88.90mm | 34.00 | 33.00 | 32.00 | 31.00 | 30.00 |